AI-Powered Solution for Stronger, More Ductile Alloys

South Korean researchers have achieved a significant breakthrough in materials science, using artificial intelligence to dramatically improve the properties of a widely used titanium alloy. A team from the Korea Advanced Institute of Science & Technology (KAIST), collaborating with researchers from POSTECH, has successfully addressed the strength-ductility dilemma inherent in Ti-6Al-4V alloy, paving the way for enhanced 3D-printed metal products.

Laser powder bed fusion (LPBF) is frequently employed in 3D printing Ti-6Al-4V, a material known for its high strength and biocompatibility. However, a key challenge has been the difficulty in simultaneously achieving both high strength and high ductility. The KAIST team’s AI accurately predicts and refines the 3D printing process parameters to optimize the alloy’s mechanical characteristics.

The AI Advantage

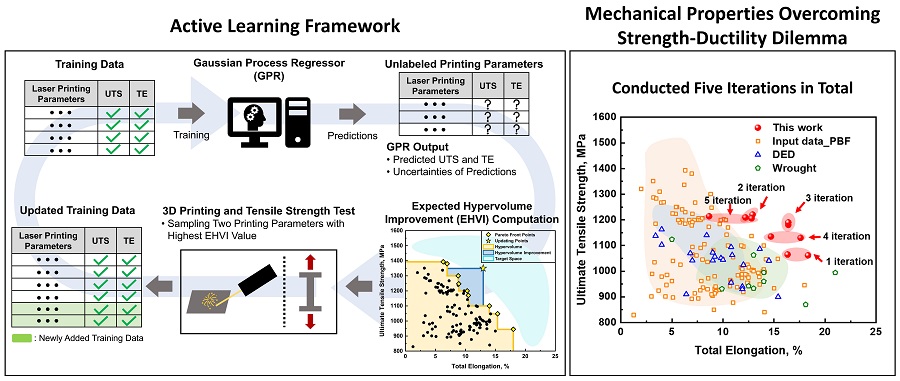

The research team developed an active learning framework, which efficiently explored a range of 3D printing parameters and heat treatment conditions. The AI model predicted the ultimate tensile strength and total elongation for each set of parameters, including uncertainty information. These predictions guided the selection of optimal conditions for 3D printing and tensile testing.

Experiments validated the model’s recommendations. Data from the experiments were then incorporated into further AI training, allowing the algorithm to iteratively refine its recommendations through just five iterations. This approach successfully identified the ideal process parameters and heat treatment conditions to produce high-performance alloys.

Results: A New Standard

With these optimized conditions, the 3D-printed Ti-6Al-4V alloy demonstrated an ultimate tensile strength of 1190 MPa and a total elongation of 16.5%, effectively surpassing the strength-ductility limitations. Professor Seungchul Lee highlighted the significance of these results:

“In this study, by optimizing the 3D printing process parameters and heat treatment conditions, we were able to develop a high-strength, high-ductility Ti-6Al-4V alloy with minimal experimentation trials.”

Professor Lee further noted that the team’s methods produced an alloy that outperforms previous studies, achieving similar strength with improved ductility.

“Furthermore, if our approach is applied not only to mechanical properties but also to other properties such as thermal conductivity and thermal expansion, we anticipate that it will enable efficient exploration of 3D printing process parameters and heat treatment conditions.”

This research, published in Nature Communications, was supported by the National Research Foundation of Korea’s Nano & Material Technology Development Program and the Leading Research Center Program.