Manufacturing Agentic AI: Unlocking New Value for Manufacturers

By Richard Humphreys | March 28, 2025

Industrial enterprises worldwide generated nearly two zettabytes of data in 2023, a figure expected to double within five years, according to ABI Research. Despite this massive data generation, much of this valuable information remains underutilized. However, with the rise of new technologies and AI, manufacturers can now harness this data in unprecedented ways, unlocking efficiency, agility, and innovation.

Technologies such as Azure IoT Operations, Microsoft Fabric, Azure AI, and Copilot Studio are bridging the gap between legacy data and modern AI-driven insights, enabling factories to become smarter, more responsive, and highly connected.

At the heart of this transformation lies the digital thread. Rupert Stuetzle, general manager of manufacturing and mobility in EMEA for Microsoft Germany, explains, “The digital thread revolutionizes manufacturing and quality control by seamlessly connecting data across the entire product lifecycle, enabling real-time problem-solving, enhanced efficiency, and improved customer satisfaction.”

Consider a quality control manager at a large electronics manufacturer who receives reports of a recurring component issue, leading to a product recall. Historically, the only solution would be a full recall, with significant financial and reputational consequences. However, with the digital thread providing comprehensive visibility into the organization’s data, the manager can trace the entire production history of the defective product, from design to final assembly, with a few clicks.

Stuetzle adds, “The digital thread helps you to quickly identify a fault in a specific batch of components sourced from a single supplier. Armed with this insight, you can determine the exact scope of the affected products, work with the supplier to amend the situation, and initiate an extremely precise, targeted recall. This swift, data-driven response mitigates customer inconvenience and helps preserve a brand’s reputation.”

A digital thread connects data, processes, and information across a product’s entire lifecycle, making it easier to track and improve decisions. It links everything from research and development to production and even end-of-life management. By combining operational technology (OT) – like sensors, machines, and factory systems – with information technology (IT), the digital thread offers manufacturers a complete view of their operations in real-time.

The first step in building a digital thread is data collection. Stuetzle states, “To create the thread, manufacturers must develop a seamless flow of data from the physical environment of the factory to the digital environment of the cloud. As a smart factory can generate up to a petabyte of data per day, it is critical to ensure all industrial data is collected, consolidated, and processed in a consistent manner across the cloud-to-edge continuum.”

Microsoft Azure IoT Operations simplifies the integration of OT and IT systems, making it easier to collect necessary data for the digital thread. Once stored in the cloud, this data is organized and structured using tools like manufacturing data solutions in Microsoft Fabric. Generative AI can then analyze the data to uncover valuable insights that help improve operations.

Stuetzle explains, “Manufacturing data solutions in Microsoft Fabric bring disparate pieces of information together, from OT sources like factory sensor telemetry to IT data like inventory details, into a unified data foundation, following an industry-standard information model. By providing a scalable and repeatable pattern to address all factory domain data projects, this data flow creates the digital thread: a consolidated view of all customer relationship management, product lifecycle management, enterprise resource planning, and manufacturing execution systems, just to name a few. With each of these key pieces of IT, OT, and engineering technology data under one roof, manufacturers are empowered with more visibility into their enterprise and factory data than ever before. When a large language model is layered on top of this foundation, employees can access the digital thread using conversational input and receive answers in real-time in their native tongue.”

Manufacturers such as Schaeffler, Bridgestone, and IPG are already leveraging this technology to unlock the full value of their factory data.

Schaeffler, a manufacturer of precision mobility components, leverages this technology to modernize data management processes and generate valuable insights across various IT and OT systems. AI-driven insights maximize machinery uptime, improve product quality, and increase output by providing employees with quick, useful information in real-time.

Bridgestone, the world’s largest tire and rubber company, is using manufacturing data solutions in Microsoft Fabric to improve the productivity of its frontline workforce.

“As a private preview customer, and in collaboration with Avanade, Bridgestone uses the digital thread and AI technology to address key production challenges, like yield loss,” says Stuetzle. “The query system solution enables frontline workers, with various levels of experience, to interact with their factory data easily and efficiently uncover insights to improve yield and enhance quality.”

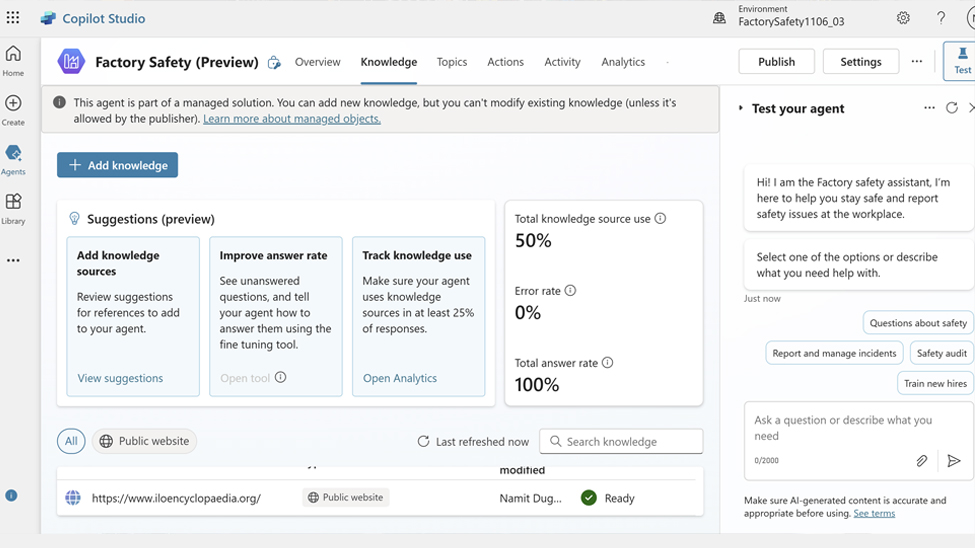

Agent templates in Microsoft Copilot Studio provide a low-code, customizable solution designed to minimize time spent on menial tasks, allowing frontline employees to dedicate their time to more rewarding work.

Stuetzle notes, “Agent templates in Microsoft Copilot Studio provide the foundation for custom copilots, which act as the user interface for the digital thread. Agent templates are low-code solutions specifically designed to address key challenges manufacturers face, like ensuring workplace safety, addressing skilled labor shortages, and enhancing operational efficiency. For example, to improve occupational health and safety compliance, a manufacturer can leverage the Factory Safety Agent in Copilot Studio, customize it to reference the unique documentation of their organization, and embed it into familiar platforms, like Microsoft Teams, to facilitate a seamless user experience. Then, when a frontline worker has a safety question, they can get immediate answers in natural language without skipping a beat.”

For plant or operations managers, agent templates serve as a valuable tool to improve operational efficiency, as the Factory Operations Agent provides real-time factory floor insights in natural language.

Stuetzle concludes, “By making it quicker than ever before to uncover answers, agent templates save time for the people of manufacturing, from the shop floor to the top floor. With tasks like data pulls and finding documents handled by AI, employees can devote their time to their most impactful work. In this way, agent templates on Copilot Studio create more productive organizations and unlock new value for manufacturers.”